Technical design and cost evaluation for precast factories

Preconsult supplies technology for the precast concrete industry.

We supply technical equipment from manual to fully automated factories for precast concrete products tailored to your requirements.

We serve your project from planning to realization and manage your project in the start-up phase.

- Design and Construction of Concrete Precast Factories

- Selection of constituent material for concrete including concrete mix design

- Selection of steel and fastening systems

- Homologation of sleeper design

Concrete Sleeper Factory Technology

Simple version for a quick commencement in specific cases

This version of a concrete sleeper factory puts the focus on short-term availability and fastest possible commencement of production. Compromise must be made at the maximum capacity, also the sleeper types should be limited to a few numbers only.

This version is particularly designed to cover the period until one of the factories as described hereinafter are designed and built and for smaller projects in difficult to access areas of Africa, South America, or similar areas.

Semi automatically version

This version is particularly suitable in countries with low labour costs and a lower standard of technical education. Such a factory is designed as a circulation system in which the concrete sleepers are been manufactured in steel moulds as described before with immediate bond of the pre-tension steel rods. Especially profiled high-strength steel tendons are getting pre-stressed within the pre-stressing frame. After sufficient hardening of the concrete the pre-stressing force will be released into the concrete sleepers.

Fully automatically version for highest flexibility and productivity

The fully automatic version is suitable for countries with high labour costs but implies a high level of trained and educated staff in the fields of mechanic and electronic. The capacity of such kind of factory will be tailored according to the specifications of the customer.

Turnout Sleeper Factory

Based on the aforementioned concrete shells also for Turnout Sleepers a new production procedure was developed. Turnout sleepers in its different length will be produced in single concrete shells, the prestressing force is getting hold by an encompassed steel frame. The advantages of the mould system as described above will be the same.

The fresh concrete will be distributed with a concrete spreader moved by a crane. The concrete is getting compacted with High Frequency Turbine Vibrators.

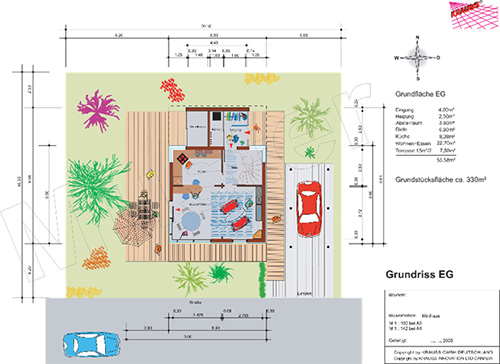

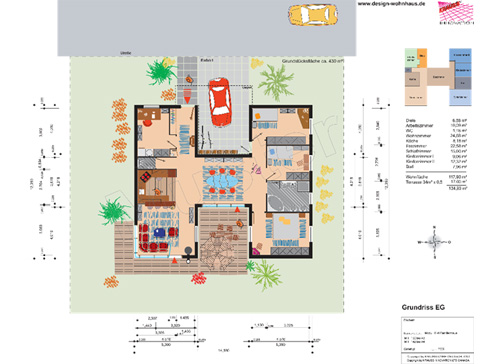

Mobile Precast factory for Housing Project

The Concept

Precast Houses in Standard Designs, samples below are protected by copyright. Single Panels transported to site and assembled there.

The Realization

Precast Factory with Battery Moulds, sample shown above.

20 Concrete panels (up to 3.5m x 7m) been casted in once with finished surfaces including conduits for e.g. electrical installation.

The panels are transported to site on flatbed trucks. At site the panels are positioned and fixed to a complete house.